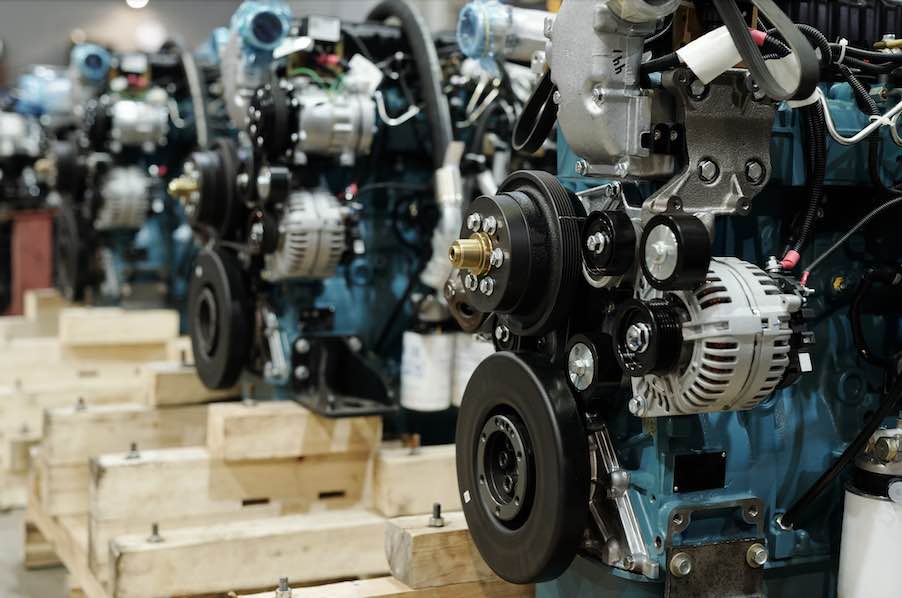

Before a vehicle ever hits the road, its journey begins with how its core components, transmissions, and engines start their journey to the assembly line. The way transmissions and engines are packaged and shipped influences the efficiency, safety, and cost of vehicle production. This packaging for powertrain components, as well as insights and strategies to optimize this crucial aspect of the automotive industry, is the first step in ensuring that shipping is the most effective.

Efficiency in Powertrain Packaging

Streamlining Logistics

Efficient powertrain packaging begins with optimizing logistics. By designing packaging that maximizes space utilization and minimizes weight, companies can reduce transportation costs and environmental impact. For instance, modular and stackable packaging solutions can significantly improve the use of container space, resulting in fewer shipments and lower fuel consumption.

Safety and Standardization

Safety and standardization are key drivers of efficiency. With the size and scope of powertrains, the way they’re packaged requires engineered solutions for care in handling. Standardized packaging dimensions and materials also facilitate easier handling, storage, and transportation, further streamlining the supply chain.

Material Selection

Choosing the right materials is crucial for maintaining efficiency. Lightweight yet durable materials such as high-density polyethylene or corrugated packaging can provide the necessary protection for powertrain components while keeping shipping weights down. Recyclable and reusable materials also contribute to sustainability efforts and cost savings in the long run. We use non-contaminating TPUs for contact points, which prevents seal leaks or pump failures in certain applications.

Safety in Powertrain Packaging

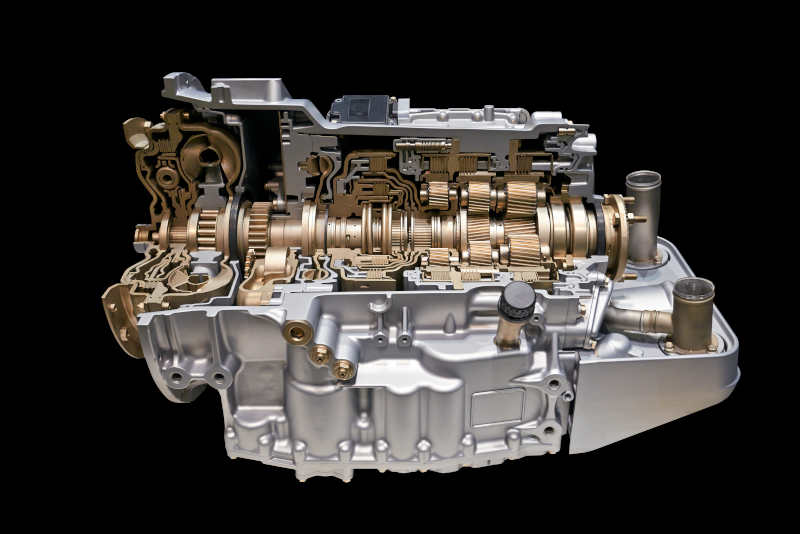

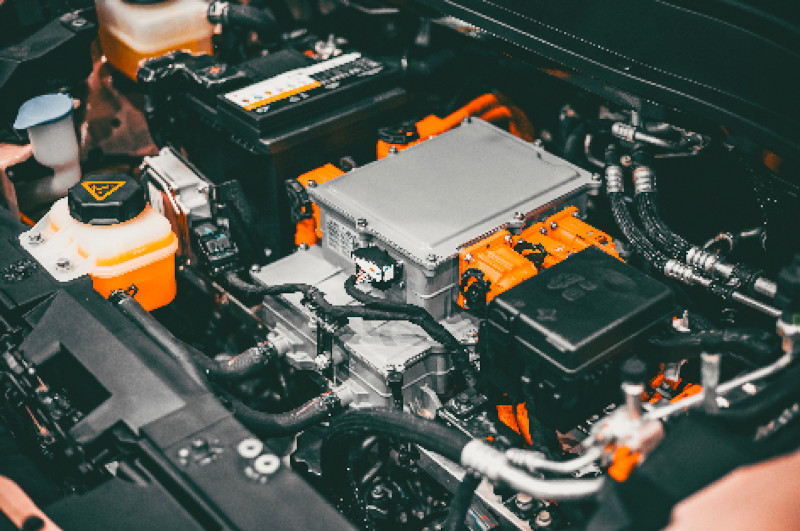

Protection from Damage

Safety is paramount in powertrain packaging. Components must be protected from physical damage, environmental factors, and contamination during transit. Custom-fit packaging solutions, such as foam inserts or injection-molded trays, can securely hold components in place, reducing the risk of damage from movement or impact.

Compliance with Regulations

Compliance with industry regulations and standards is essential for ensuring safety. Packaging engineers must be well-versed in the latest guidelines for shipping automotive components, including hazardous materials regulations and international shipping standards. Adhering to these regulations not only ensures the safety of the components but also avoids costly fines and delays.

Ergonomics and Worker Safety

The safety of workers handling powertrain packaging is also a critical consideration. Ergonomically designed packaging that is designed specifically for large powertrain components can prevent workplace injuries and improve overall efficiency.

Cost Considerations in Powertrain Packaging

Balancing Cost and Quality

Balancing cost and quality is a constant challenge in powertrain packaging. While it may be tempting to opt for the cheapest materials and designs, this can lead to higher costs in the long term due to damage, inefficiency, and non-compliance issues. Investing in high-quality, durable packaging solutions can lead to significant savings over time.

Reducing Waste

Reducing waste is another critical factor in controlling costs. Designing packaging that minimizes excess material and can be easily recycled or reused helps lower waste disposal costs and supports sustainability initiatives. Returnable packaging systems, where packaging materials are sent back to the supplier for reuse, are an effective way to reduce waste and costs.

Optimizing Inventory Management

Effective inventory management can also contribute to cost savings. By implementing just-in-time inventory strategies and using packaging that facilitates easy inventory tracking and management, companies can reduce storage costs and minimize the risk of overproduction or stockouts.

Safe, Efficient, and Cost-Effective Packaging is Within Reach

In conclusion, efficient, safe, and cost-effective powertrain packaging is essential for the success of automotive manufacturing. By focusing on optimizing logistics, material selection, safety measures, and cost management, OEMs can significantly enhance their operations and contribute to the overall sustainability and profitability of the industry.

To learn more about innovative powertrain packaging solutions and how PCD can benefit your operations, explore our comprehensive resources and expert insights. Stay ahead of the curve and ensure your packaging practices are setting the standard for efficiency, safety, and cost-effectiveness in the automotive industry. We want to hear from you; contact us here.