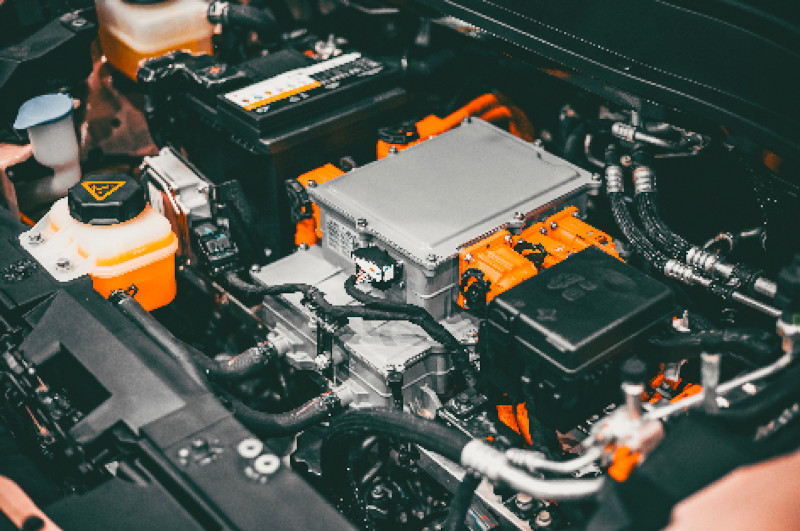

Over the past decade, the electric vehicle (EV) industry has exploded. Their cost-saving and energy-saving features attract a younger, environmentally conscious generation, but due to their lofty price tags, EVs have yet to become mainstream. However, as companies like Tesla race to produce affordable EVs, auto manufacturers who hope to stay ahead of the alternative energy trend need to think about one important thing: how to ship EV batteries.

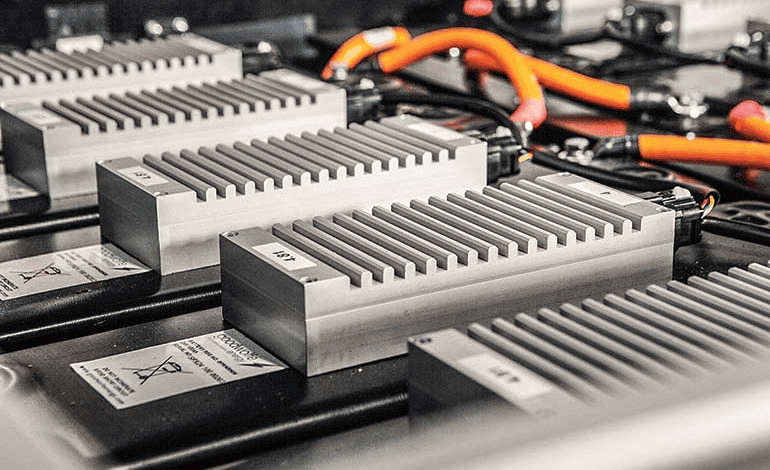

EVs rely on lithium ion batteries as their source of power – and shipping these massive battery packs is no small feat. So, here’s a few tips.

“Dangerous Goods”

We’ve all heard stories about cell phones and laptops exploding. These stories illustrate how lithium ion batteries can be dangerous. And, how they require a lot of protection during transit. All lithium ion batteries are considered hazardous material by the Department of Transportation. There are many rules, regulations and restrictions for shipping them (you can read an overview here), but the size of EV batteries further complicates packaging design and transport.

Inner and Outer Packaging

Having a strong inner and outer packaging design will protect the battery and meet DOT regulations. There are two primary considerations:

- Each battery must be separated from one another

- Preventing battery movement inside the packaging is crucial

Cushioning materials like urethane or any foam provide vibration damping and impact resistance.

For outer packaging, there are several design options to help comply with DOT requirements for your product

Plywood Boxes

These boxes are made from a combination of wood and steel. They are strong but lightweight and suitable for heavy EV batteries.

Corrugated Board

Corrugated boxes are lined with fitted Expanded Polypropylene foam to keep EV batteries from jostling during shipment. They are then stacked and secured to pallets. Their light weight and small size save space and freight costs.

Custom Packaging Materials

Depending on your needs and battery size, customized packaging may be the way to go (though we recommend custom packaging is always the best choice). Team up with the right packaging design firm that can meet DOT regulations while providing a cost-saving solution.

Whatever your lithium ion packaging needs, PCD is here to help. We have extensive design experience, vast knowledge of a variety of industries, and superior levels of customer service. And, designing packaging to optimize your supply chain and reduce your total landed costs is our specialty! If you’d like to see if we are the right packaging solution firm for you, don’t hesitate to contact us!