Damaged packaging has direct and indirect consequences. Direct consequences, or measurable outcomes, like profit loss and the cost of replacement shipping are obvious. However, indirect consequences, like lost time, increased labor and company reputation aren’t always quantifiable or assessed – but they have costly repercussions. Here’s how (and why it’s necessary) to reduce packaging damage throughout your supply chain.

Properly Secure Loads to Pallets

A study by Kansas State University found that load damage was the No. 1 cause of supply chain interruptions. Packaging damage occurred due to the jolts of forklifts crossing dock levelers onto trailers. If packaging is loose or overhanging, you risk damaging your product. Therefore, pallet quality and load size are key to reducing packaging damage altogether.

Inspect Pallets

It isn’t uncommon for wood pallets to lose a nail or two, crack or soften due to moisture or changes in temperature. Weak pallets are begging for accidents, so if you aren’t regularly performing quality checks, it’s time you start.

Optimize Pallet Loads

Cubing is key here. Depending on the size of your packaging and pallets, geometry has proven repeatedly that there is an optimal load size. If you’re piling too many boxes on pallets, you risk stressing the wood. Too few, and you’ve you lost precious truck space. This is why it’s so important to…

Upgrade Your Packaging Design

The ROI of custom designed packaging far exceeds the cost of product damage and supply chain interruptions. So, if you aren’t a packaging engineer,hire one. They will consider every element of your supply chain and work from the biggest box (truck bed, shipping container, etc.,) backwards. The benefit is space and load optimization that lower your overall costs and prevents packaging damage. This way, instead of following general loading advice, like stacking heavier boxes in an overlapping pattern, you will have a system backed by math.

Design Elements to Consider

- Fluting and Wall Construction: The materials you use to ship product should be high-quality. Ensure heavier items are placed within a double-wall box with properdunnage. However, with the many types of fluting available on the market (horizontal and vertical), picking the right kind of corrugate is a must. The truth is: some corrugate is better for certain items, and some is better for others. Lighter items should also be packaged in a way that optimizes for space and safety. Always use a durable plastic tape to seal cardboard boxes.

- Stretch Wrap: Is stretch wrap used properly? Are you using too much or too little? Is this material actually necessary? Whether or not stretch wrap prevents damage is largely due to its proper application. Another thing to consider is stretch wrap’s force-to-load measurement, or the amount pounds of strength/force applied to hold the product together.

- Weather-Resistant Materials: Depending on where you’re shipping, traditional cardboard boxes may not be doing their job. Evaluate your shipping route to determine what natural elements your packaging will face and know that heat and humidity are your two biggest concerns.

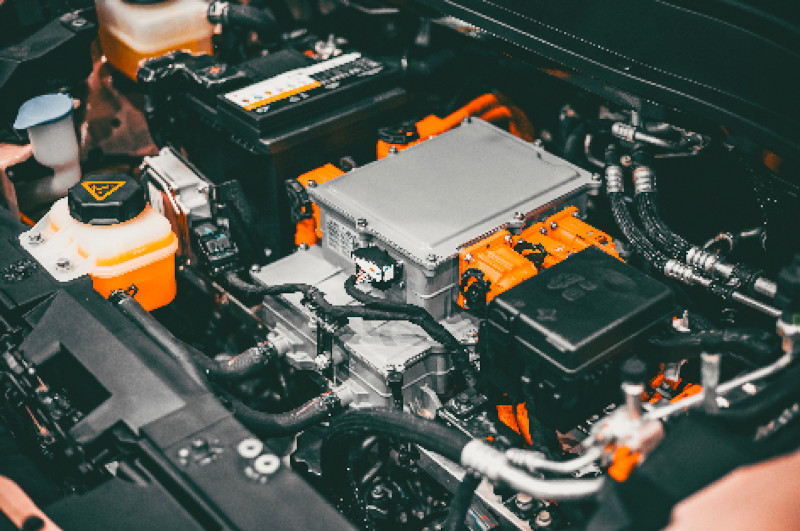

Most importantly, packaging damage affects the customer. And the customer’s customer. If they must wait on a product or part to continue their operations, they waste time, money and product. For example, in 2017, a Czech Republic-based automotive supplier caught fire, causing several global OEMs to halt production. The point is: whether due to fire or mother nature, damaged packaging has detrimental ripple effects.

So, if you’re experiencing packaging damage in your supply chain, PCD is here to help. We are experts at packaging design and can offer solutions that improve your entire supply chain. If you have any questions, don’t hesitate to contact us.