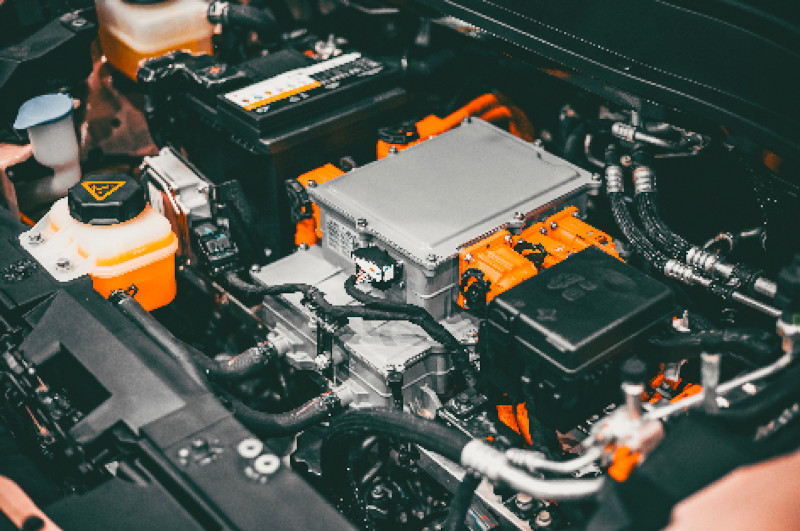

As the electric vehicle (EV) market grows, the need for packaging that’s efficient, scalable and cost-effective is more important than ever. EV powertrains—made up of components like lithium-ion battery packs, motor-drive controllers, power electronics, and traction motors—come in all sizes and shapes, making protection during shipping a challenge.

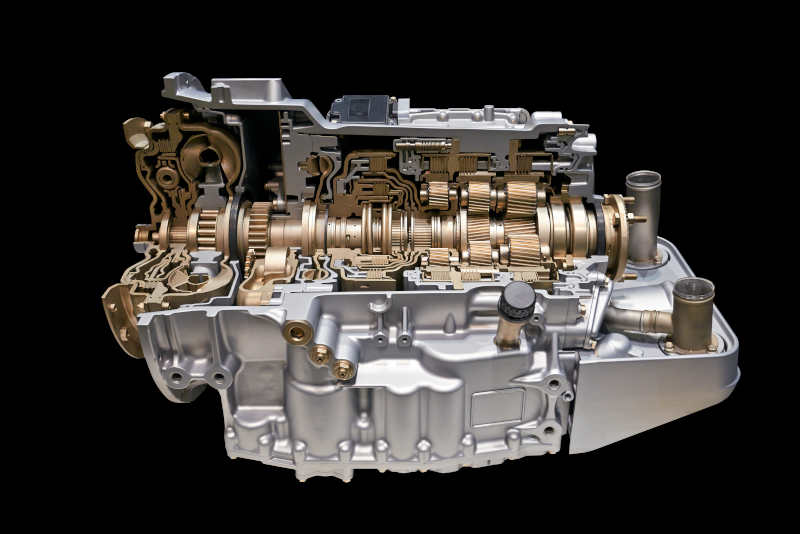

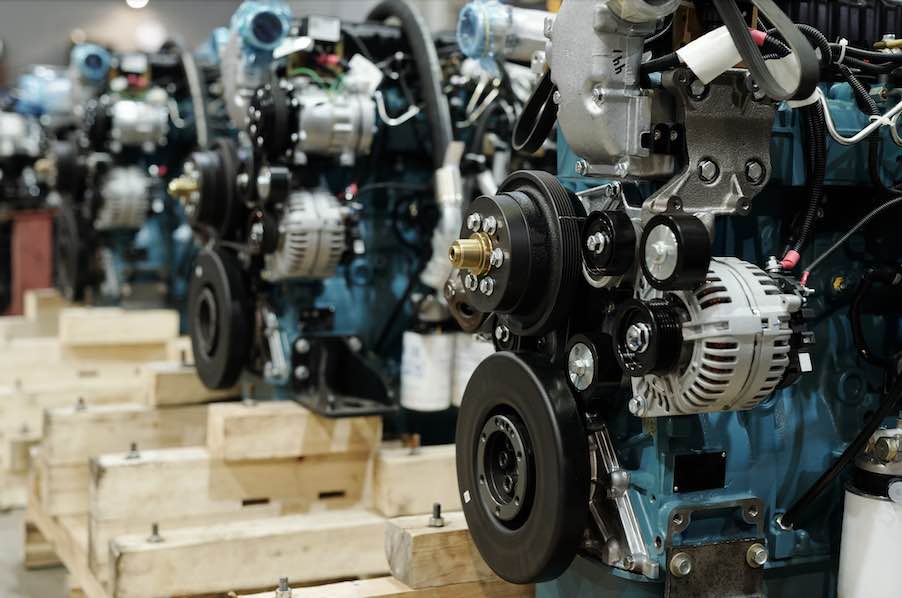

Add internal combustion engines (ICE) and transmissions found in hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) and things get even more complex. This variety in powertrain configurations makes customized packaging solutions absolutely essential to ensure all components arrive at their destination safely intact.

Packaging customization is necessary — there’s no way around it

- Unique Component Shapes and Sizes: The components in an EV powertrain come in a variety of shapes. A battery pack, for example, is very different from a motor-drive controller or an ICE. Standard packaging just doesn’t cut it because it doesn’t account for these differences, which can lead to damage during shipping. That’s where custom-designed packaging comes in. It’s made to fit each part perfectly, keeping everything secure and minimizing any movement or potential damage. This tailored approach is crucial for protecting both the delicate electronics and the heavier, bulkier components.

- Better Protection During Shipping: Moving EV powertrain components from one place to another comes with a lot of risks. Things like vibrations, shocks, and exposure to the elements can easily damage these parts. That’s why customized packaging is so important—it’s specifically designed to handle these challenges. Using specialized cushioning materials like foam inserts and custom containers can significantly reduce the risk –and costs– of damage. Plus, for sensitive components like battery packs, added safety features like tamper-evident seals and hazardous material labels are a must. These ensure everything is handled safely and meets all legal regulations during transport.

- Scalability and Efficiency: With the EV industry booming, packaging needs to keep up with the growing production demands. Custom packaging isn’t just about protection—it’s also about efficiency. When each component is perfectly fitted, manufacturers can make the most of available space, whether in storage or during shipping. This precise fit means you use less packaging material overall and can pack more components into a single shipment. The result? Lower transportation costs and a smoother, more efficient logistics process.

- Adapting to Supply Chain Needs: A good packaging strategy isn’t just about the box itself—it’s about understanding the whole supply chain. This means thinking about how the package will be transported, handled, and stored. Custom packaging needs to adapt to all these factors, making sure the components stay protected from the moment they’re made until they reach their final destination. This kind of flexibility is key, especially in a global supply chain where conditions can vary widely from one place to another.

- Keeping Sustainability in Mind: With sustainability being a big focus in manufacturing, packaging has to step up to meet environmental standards too. Custom packaging makes it easier to use recyclable or biodegradable materials, which helps cut down on waste and reduce the carbon footprint of the packaging process. By designing packaging that’s both protective and eco-friendly, manufacturers can support their sustainability goals without compromising the quality of their products.

In the ever-changing EV industry, it’s clear that custom packaging solutions are essential. As manufacturers look to protect their intricate and valuable components, cut costs, and expand their operations, they need a packaging partner who can offer tailored, efficient, and eco-friendly solutions. Investing in custom-designed packaging ensures that EV powertrain components are transported safely and cost-effectively, meeting the needs of a booming market while keeping up high standards of quality and safety.

PCD is here to support those needs and understands the unique demands of EV powertrains. PCD can provide flexible, custom solutions that are key to the ongoing success and growth of any EV manufacturer. We specialize in innovative, custom packaging design and have experience working with manufacturers across several industry sectors. Our North American footprint means we’re able to assist you wherever you are. Feel free to reach out with any questions – we’re here to help. contact us!