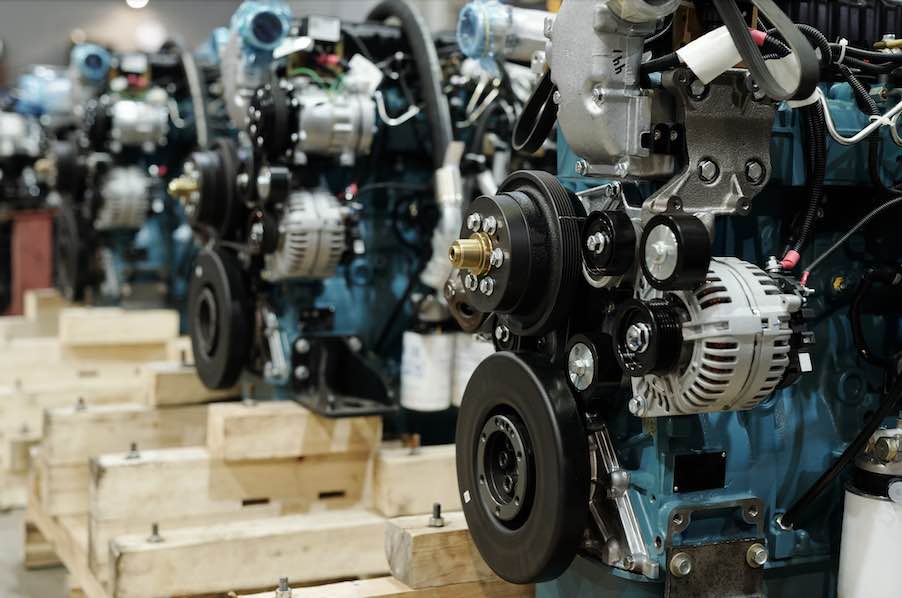

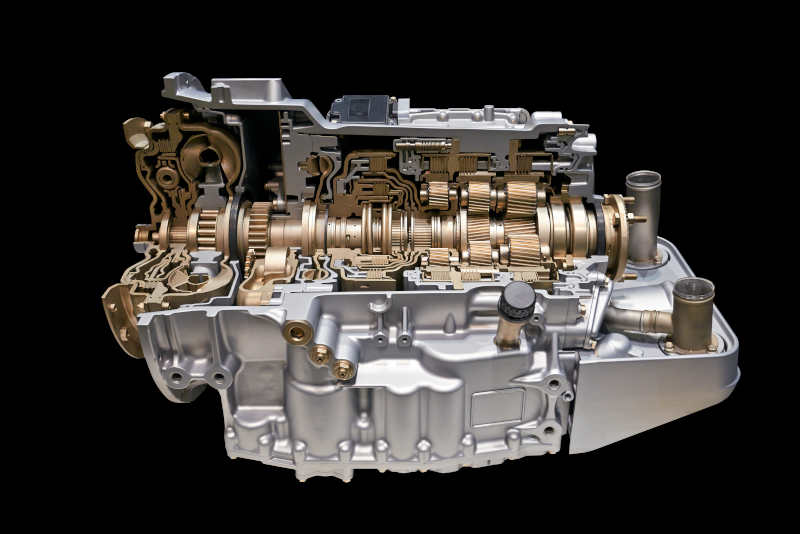

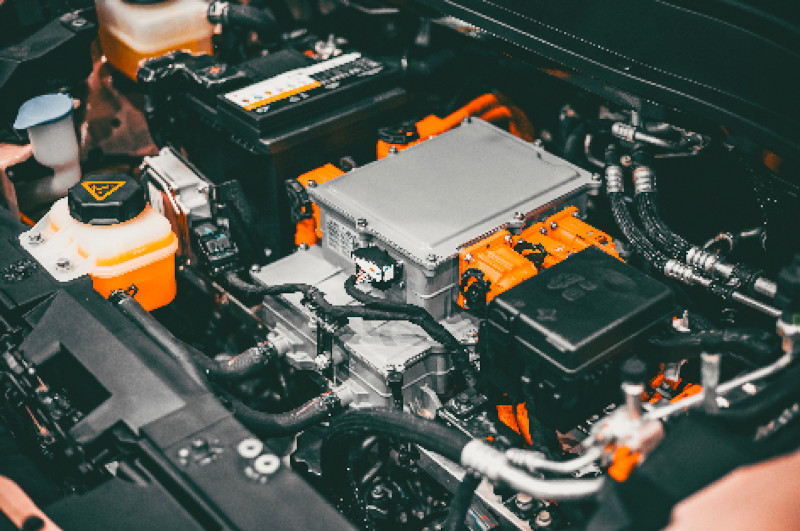

When it comes to transporting heavy and bulky powertrain components such as engines and transmissions, custom packaging solutions play a crucial role in ensuring these valuable parts arrive at their destination safely and efficiently. Given the size, weight, and complexity of these components, standard packaging options often fall short. Here are 5 packaging solutions for strength, stability and ease of handling.

1. Reinforced Packaging Materials

Strength and Durability: Heavy and bulky components demand packaging materials that can withstand significant stress. Reinforced corrugated cardboard, double-wall or triple-wall variations, and high-density polyethylene (HDPE) are excellent choices. For instance, using triple-wall corrugated cardboard provides exceptional strength and impact resistance, ideal for supporting the weight of engines during transport.

Custom Crates and Pallets: Opt for custom-designed wooden or metal crates and pallets that are built to support the specific dimensions and weight of your components. Wooden crates with reinforced corners and metal banding can enhance durability and load-bearing capacity. Ensure that these crates are treated and finished to withstand environmental conditions like moisture and temperature changes.

2. Effective Cushioning and Padding

Foam Inserts: Use high-density foam inserts, such as polyurethane or expanded polystyrene (EPS), to cushion components and prevent movement within the packaging. Custom-cut foam inserts can be tailored to fit the precise contours of engines and transmissions, offering superior shock absorption and protection from vibrations.

Bubble Packaging: Consider using inflatable air cushions or airbags for additional cushioning. These can be placed around components to fill voids and provide a protective layer that absorbs shocks and vibrations during transport.

3. Secure Fastening and Stabilization

Strapping and Banding: Implement heavy-duty strapping or banding to secure components within their packaging. This method prevents movement and reduces the risk of damage caused by shifting during transit. Steel or nylon straps can be used depending on the weight and fragility of the component.

Internal Bracing: For added stability, design internal bracing systems within crates or containers. These can be made from wood or metal and are used to brace components against the walls of the packaging, minimizing movement and preventing potential impacts.

4. Ease of Handling and Transportation

Ergonomic Design: Design packaging with ergonomic features such as handles, lifting points, or forklifts slots to facilitate easier handling. For instance, including reinforced handles or hand-holds in crates allows for safer and more convenient lifting and maneuvering.

Modular and Stackable Solutions: Create packaging solutions that are stackable and modular, allowing for efficient use of space during storage and transport. Stackable crates or containers can help maximize storage space in shipping containers and reduce shipping costs.

5. Environmental Protection

Climate Control: Incorporate climate control measures if components are sensitive to temperature and humidity. For example, use moisture-resistant liners or desiccants to protect against humidity and corrosion. Insulated packaging can help maintain stable temperatures during transit.

Weather-Resistant Coatings: Apply weather-resistant coatings or covers to packaging to protect against rain, snow, and other environmental factors. This ensures that components remain protected even if the packaging is exposed to harsh weather conditions during transport.

By focusing on these key areas, you can develop custom packaging solutions that effectively address the unique challenges of transporting heavy and bulky powertrain components. Tailored packaging not only ensures the safe and efficient delivery of your components but also enhances overall operational efficiency and cost-effectiveness in your supply chain.

PCD is also here to help! We specialize in innovative, custom packaging design and have experience working with manufacturers across several industry sectors. Our North American footprint means we’re able to assist you wherever you are. Feel free to reach out with any questions – we’re here to help. contact us!