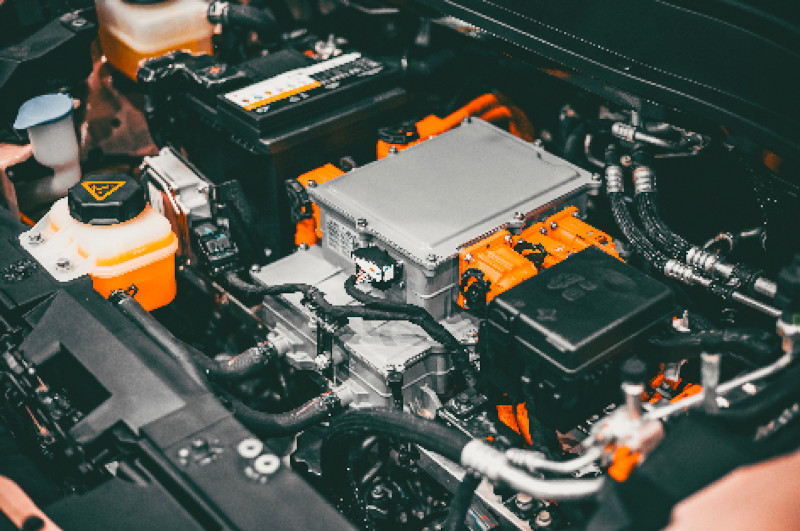

Typically, people associate the words “green” and “sustainable” with products made from recyclable materials. However, in the manufacturing supply chain, returnable packaging sometimes makes sense and sometimes doesn’t. This is especially true for international shipping and for items with mandated packaging requirements (like lithium ion batteries). And while going green often has financial and supply chain benefits, when it isn’t feasible, [JG1] sustainable practices are still an option. So, here are four practices that lend themselves to a green supply chain.

1. Optimize Your Packaging Design

We can’t stress this enough: efficient packaging lowers supply chain costs and increases supply chain efficiency. Using the proper box size, dunnage, and cubing methods reserves space, reduces labor and minimizes packaging waste. This should be a strategic goal within your organization and has been proven to improve packaging’s environmental performance. It’s a win-win-win.

2. Reduce Storage Space

If your supply chain isn’t working efficiently, it’s likely that you’re using too much storage space. Oddly enough, this could be the result of an unpredictable supply chain that demands reusable packaging. If suppliers don’t know when customers will place orders or can’t anticipate how much packaging they’ll need, packaging materials may sit for weeks at a time, get damaged, go unused, or get thrown away. Also, the amount of labor required to disassemble and reassemble packaging wastes time and operational energy. This comes at a huge cost to both your company and the environment. The best way to reduce storage space? Develop an efficient packaging system.

3. Minimize Supply Chain Waste

An optimized packaging design that reduces supply chain waste naturally leads to organizational, financial, and environmental improvements. Additionally, taking steps to minimize packaging damage is an environment and waste saver. This includes properly loading boxes to pallets, inspecting pallets regularly for damage, and selecting the right materials to secure and protect the shipment.

4. Reduce Production Energy

Reducing the energy it takes to produce packaging improves its green performance. Evaluate any emissions released in the air or water, anticipate the likelihood of pollution, and consider reusing and recovering materials if at all possible.

We have extensive experience designing packaging that meets our clients’ green supply chain needs. If you’d like to learn more about sustainable supply chains or how to reduce your operational costs, don’t hesitate to contact us!